The maintenance of fire pump sets should strictly follow the maintenance system so that the fire pump units can always maintain a good technical condition and clean appearance and be ready for combat readiness to respond quickly and effectively in case of emergency and put out fires in time.

The packaged fire pump shall be subject to weekly inspection, monthly inspection, mid-year inspection, and annual inspection.

1. Weekly maintenance

- Valves and Pipeline. Check the inlet and outlet pipelines of the pipeline and each valve to ensure that they are open and free from leakage

- Autostart Function. Check this function, please run the test pipe to prevent reducing the pressure on the main pipeline. For diesel engines, run at the rated speed for at least 30 minutes in order to warm up and stabilize all operating components, thus reducing condensation and moisture and increasing the life of important engine components. For the motor, check the start-up operation and run for at least 10 minutes

- Control cabinet. Check if the alarm system is normal. Check the automatic starting mode of the control cabinet. Verify remote monitoring alarm receipt in automatic start test

- Safety valve. Check whether the safety valve operates normally. Usually, water does not pass through the safety valve during operation. The safety valve is designed to maintain the pressure of the pipeline and play a safety protection role in the system. When the system pressure exceeds the specified value, the safety valve opens to discharge part of the gas/fluid in the system out of the atmosphere/pipeline so that the system pressure does not exceed the allowable value, thus ensuring that the system does not suffer from accidents due to excessive pressure.

- The inspection of the water supply system. Visually inspect the water supply box or water source. In cold weather, please ensure the temperature of the environment at the water supply pipe and water intake to prevent water from freezing, and check the water source for possible obstructions blocking the pipe. In dry conditions, make sure the water source is adequate. For the common jockey pump, check all valves on the suction line.

- Pump room temperature. The minimum temperature of the pump room should be 4 ℃, and for pump room with the internal combustion engine, the recommended minimum temperature is 21 ℃.

- Diesel engine. Please make sure the diesel engine is clean, neat, dry and running normally.

Check as follows

- Tank Level: When the level is less than three-quarters of the entire tank level, the tank must be filled

- Make sure that all valves from the tank to the drive, or in the pump system, are locked in the open position

- Use the oil level of the dipstick on the engine crankcase

- Is the battery charger and battery working properly

- Cleanliness of Engine Cooling System Screen

- Clean the screen if necessary

- Pay attention to the temperature of the cooling system

- Ensure that the flow of water in the heat exchanger ( if present ) is sufficient.

- Is the engine running normally, such as speed, oil pressure, temperature, etc

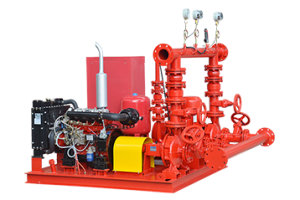

XBC6-25-IS end suction fire fighting package set

1. monthly maintenance

Check the detection level and specific gravity of diesel battery electrolyte

Check the corrosion of diesel battery terminals and cable lines and connections

2. mid-year inspection

Change the oil

3. annual inspection

- Water flow test

Please be sure to perform the water flow test at least once a year. If you have technical problems, please consult with engineers from Better Technology CO., LTD. Here are some steps.

- Record the data of each measurement, the data of inlet and outlet under different flow conditions, which can be plotted on the rating chart as a method to help calculate the pump performance. It can also be compared with the data given by the factory.

- At least three pump curves ( zero flow rate, rated flow rate, 1.5 times flow rate ) with flow rate and pressure readings need to be found and corrected in time if the required flow rate cannot be met or there is a big change.

- Drain water to a safe position through fire hydrant or hose header or flowmeter

- Pump Coupling

- Calibration of coupling

- Lubrication of coupling