Fire pump long-term operation common problems and solutions

In the long-term operation of fire pumps, there are often large and small problems, we need to understand how it is maintained:

In the above problems, the common solution for enterprises is to repair the welding or brushing machine, but they all have some shortcomings: the high temperature welding repair for thermal stress can not be completely eliminated, which is easy to cause material damage, resulting in bending or breaking composition; and brush plating The thickness of the coating is limited and it is easy to peel off. The above two methods are all used to repair the metal with metal. The “hard to hard” coordination relationship can not be changed. Under the action of force, it will cause wear. Modern Western countries have problems with the use of polymer composites, repair methods, superior adhesion, and high compressive strength.

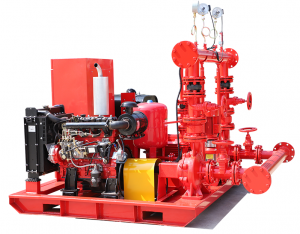

Fire pump set comprise a combination of electric driven pump, diesel driven pump and electric motor driven jockey pump that supply for fire suppression systems. Fire pump set are required to comply with Local Civil Defense Authority regulations and International Codes of Practice e.g. National Fire Protection Association (NFPA).

The application of polymer materials in repair can be exempted from removal and processing. There is no restriction on the heat of welding and the thickness of the repair is not limited. The metal materials franchised by the product can absorb the impact of the fire pump, avoid the wear and tear again, and prolong the equipment and large parts. The service life saves the company a lot of downtime and has great economic value.

1: Flame, flame-polished fire pump on the surface to soften the baking, thermal shock, can remove some surface twill, wrinkled skin, many cutting mouth will polish the mouth flame, but this treatment will reduce the smoothness of the surface of the fire pump .

2, polishing powder polishing: This method is to remove the scratches from the fire pump on the high-speed friction surface. Before polishing, the abrasive belt should be ground and polished. In which a large amount of material is used, the good effect is yttrium oxide, but This process is slow.

3, acid acid corrosion polished surface effects of fire pump surface treatment, also need to grind the fire pump in the polishing belt, because acid polishing will reduce the thickness of many equipment itself, may not be able to remove all the lines on the surface.