Cycle maintenance of long shaft deep well fire pump

The long-axis deep well fire pump adopts advanced hydraulic model and structural design, and the blade runner is made of various new technologies such as epoxy spraying. The material selection is reasonable, the product performance is excellent, and the service life is long. This series of products are mainly used in fire protection systems such as fire hydrant fire extinguishing and automatic sprinkler fire extinguishing in fixed fire protection systems such as industrial and mining enterprises, engineering construction, high-rise buildings, etc., which can transport clean water without solid particles and medium with chemical properties similar to water. It can also be used for living and production of shared water supply systems and buildings, municipal water supply and drainage, etc.

Long shaft deep well fire pump maintenance:

The periodic maintenance of the long shaft deep well fire pump mainly includes the following two aspects:

- Regularly repair and repair the long-axis deep well fire pump, once a major overhaul every year, once every three months. The minor repairs include: removing dirt and dust inside the motor; checking the grounding wire, winding joints, and fasteners of the transmission mechanism for looseness; checking the insulation resistance of the motor. The contents of the overhaul remove the minor repairs, including: checking the wear of the bearing; whether the winding is damaged or replacing the lubricant.

- After one year of operation of the long shaft deep well fire pump, it should be mentioned on the ground for overall maintenance. If the operation of the deep well pump is good after one year of operation, the overall maintenance time can be extended to two or three years, and should not exceed three years. If the deep well pump is not in use, it will run for about half an hour every week to prevent the machine from rusting.

- For the phenomenon that the temperature in the north is low in winter, the long-axis deep well fire pump should take corresponding anti-freezing measures.

- It can replace the high water tank type water tower, which not only reduces the load on the building structure, but also contributes to the earthquake resistance of the structure and greatly saves the investment of the building.

2, compact structure, small footprint, easy to install, can be placed according to the needs of the building, no need to set up a special pump room, more conducive to the transformation of the old building water supply equipment.

3, the device has a fully automatic control function, easy to manage, no need to set up a person to watch.

- Long-axis deep well fire pump adopts diaphragm type pressure tank structure, which has good air tightness and can be used for a long time after one inflation.

- The equipment can guarantee the water supply pressure required for fire water points and fire hydrants, and reserve the fire water required to ensure the main pump before starting.

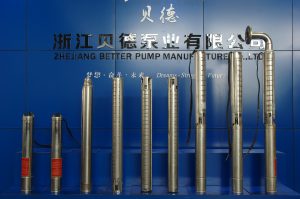

- The long shaft deep well fire pump is composed of a plurality of centrifugal impellers and a diversion shell, a water pipe, a drive shaft, a pump base, a motor and the like. The pump base and the motor are located above the pool, and the power of the motor is transmitted to the impeller shaft through a drive shaft concentric with the water pipe, thereby generating flow and pressure.